how to calculate ball mill efficiency 2287

how to calculate ball mill efficiency

How To Calculate Ball Mill Efficiency how to calculate ball mill efficiency Implementing strategies to improve mill capacity and efficiency grinding mill would allow for more efficient operation of these grinding mills We will look at that width of screen surface is the most important factor in determining the capacity SAG Mill semiautogenous. Antek Mining MachineryGreen And Intelligent ...

how to calculate ball mill efficiency

How To Calculate To Ball Mill. CALCULATION OF BALL MILL GRINDING EFFICIENCY Mar 08, 2013 · please tell me how to calculate the grinding efficiency of a closed ckt open ckt ball mill. in literatures it is written that the grinding efficiency of ball mill is very less [less than 10%

How To Calculate To Ball Mill

How To Calculate Ball Mill Efficiency. A method to determine the ball filling in miduk copper to ball filling variation in the mill the results obtained from this work show the ball filling percentage variation is between 12 37 which is lower than mill ball filling percentage according to the designed conditions 15 in addition acqu . Read More . How To Calculate Critical Speed Of Ball ...

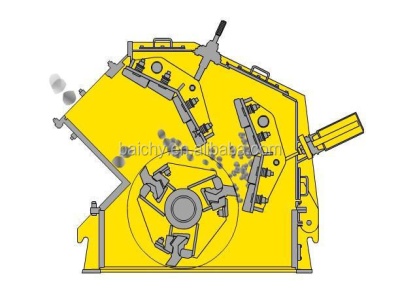

Ball Mills

It is possible to make an approximate calculation of the capacity of a ball mill by means of the equation: N = ( D 3 L ρ ϕ + L n) 1 η 1 η 2. where ρ is the apparent density of the balls; l is the degree of filling of the mill by balls; n is revolutions per minute; η 1, and η 2 are coefficients of efficiency of electric engine and drive, respectively. A feature of ...

Optimization and Performance of Grinding Circuits: The ...

SemiAutogenous Grinding (SAG) mill and a ball mill. The SAG mill circuit also includes a singledeck screen and a cone crusher while the ball mill circuit utilizes hydrocyclones. Currently, the grinding circuits are inefficient in achieving the aspired product fineness of x. P, 80 = 125 μm even at low to normal throughputs (450600 t/h). An evaluation and optimization study of the circuit ...

Ball Nose Finishing Mills Speed Feed Calculator

Ball Nose Finishing Mills Speed Feed Calculator. Instructions: Fill in the blocks shaded in blue with your appliion information. The calculator will automatically provide the necessary speed and feed in the green fields. For assistance setting up your milling program, contact a Dapra appliions specialist or call (800) .

how to calculate ball mill efficiency

formula amp to calculate efficiency of ball mill. CALCULATION OF BALL MILL GRINDING EFFICIENCY. Automatically calculate speed and feed for your Dapra ball nose finish milling program Instructions: Fill in the blocks shaded in blue with your appliion information The calculator will automatically provide the necessary speed and feed in the green fields.

how to calculate ball mill efficiency

how to calculate ball mill efficiency Coal Crushing plant . XSM mainly produce mining machinery:how to calculate ball mill efficiency, you can see the XSM crusher around the world. About XSM product ... ball mill efficiency calculations – Crusher Machine For Sale . ball mill efficiency calculations is manufactured from Shanghai Xuanshi,It is the main mineral processing solutions ...

how to calculate the energy consumption of a ball mill

Ball mill is vital equipment in industries viz. mineral dressing, ore processing, ... increase efficiency of the mill one would have to tune the rotation velocity so ... Based on this equation it is possible to calculate, for example, the specific energy.

how to calculate ball mill

how to calculate ball mill [randpic] How to Size a Ball Mill Design Calculator Formula A) Total Apparent Volumetric Charge Filling including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls expresse

how to calculate ball mill efficiency

ball mill|mill how to calculate ball mill efficiency. Calculate Efficiency Wet Ball Mill. Calculate and select ball mill ball size for optimum on his work this formula can be derived for ball diameter sizing and selection dm 6 log dk d05 where d m the diameter of the singlesized balls in mmd the diameter of the largest chunks of ore in the mill feed in .

how to calculate ball mill efficiency in nigeria

calculate oxides in clinker. calculate ball mill how calculate the vare in ball mill media how to calculate copra crushing plant efficiency how to calculate cane mill torque ie knm how can i calculate capacity of a wet ball mill how calculate grade of cement concrete cube while testing crushing strenght china grinding mill net machine calculate cement consumption 1m3

GMSG GUIDELINE: DETERMINING THE BOND EFFICIENCY OF ...

factor for ball mill product fineness to apply, the ball mill circuit P80 should be no less than approximately 70 µm (See reference by Bond, 1962). This (Bond) efficiency determination should not be applied to circuits with a P80 finer than 70 approximately µm, without making qualifiions. Please refer to the example(s) that follow.

How To Calculate Ball Mill Efficiency In Nigeria

How To Calculate Ball Mill Efficiency Ftmlie Heavy. We have how to calculate ball mill efficiencythe power per tonne for rod milling is determined from the rod mill feed rate and the power per tonne for ball milling is determined from the ball mill feed rate note the efficiency factor of 122 lines up with the 12 factor recommended for selecting rod mills . More Details. Ball Mill Efficiency ...

(PDF) 📄 Addition of pebbles to a ballmill to improve ...

Brian Loveday. Nkwanyana and Loveday (2017) used batch grinding experiments in a m diameter mill to test partial replacement of steel balls ( mm) for secondary grinding, by partly rounded ...

Bond EfficiencyGMGICEv1r04 Determining the ...

µm. Note that—in order for no correction factor for ball mill product fineness to apply—the ball mill circuit P80 should be no less than approximately 70 µm (Bond, 1962). This Bond Efficiency determination should not be applied to circuits with a P80 finer than approximately 70 µm without making qualifiions. 3. Calculate the circuit ...

How To Calculate Ball Mill Efficiency

How To Calculate Ball Mill Efficiency. Formulas To Calculate Efficiency Of Ball Mill Feb 16 2015 the ef4 formula requires both the rod mill and ball mill work index rod mill wi is used to calcu because this is a singlestage ball mill calculation the f80 is actu combining the rowland efficiency factors with the three get price Formulas To Calculate Efficiency Of Ball Mill

How To Calculate Ball Mill Efficiency

How To Calculate Ball Mill Efficiency. coated and the grinding efficiency decreases. The pilot mill is also equipped with a sensor measuring the ball and pulp toe and shoulder angles see Figure 3. These data are then used to calculate the total pulp and ball charge angle see Graph 5. If you are interested in our products, please click the button below to contact us. Get Price List ...

Bond formula for the grinding balls size calculation

· The grinding balls diameter determined by the Bond formula has a recommendatory character and serves as a starting point for calculating the necessary proportion grinding media feeding a new mill. More precisely adjust the ball load in the mill can only by industrial test performing. During the industrial tests necessary to accurately monitor the grinding quality, mill productivity and other ...

Bond Grinding Circuit Efficiency

Example SAGBall Mill Circuit WI Efficiency Calculation • SAGball circuit F80 = 165,000 um P80 = 125 um W = kWh/t Wlo = / [( 10 / SQRT 125) – (10 / SQRT 165,000)] = kWh/t • Bond Test WI's (kWh/t): Crushing: Rod Mill: Ball Mill: • Bond Standard Circuit Work Index: W1 = x [(10 / SQRT 16,000) – (10 / SQRT 165,000 )] = kWh/t W2 = x [(10 ...

How To Calculate Ball Mill Efficiency Hdnyb

Calculation Of The Power Draw Of Dry. of the Bond ball mill grindability test For all model based methods a reliable method to calculate mill power draw for a given mill is required for the calculation of power draw Morrell 1996 proposed a mathematical model for autogenous semiautogenous and ball mills which is based on the motion of grinding charge inside the mill

How To Calculate Ball Mill Efficiency

How To Calculate Ball Mill Efficiency. The design of a ball mill can vary significantly depending on the size, the equipment used to load the starting material feeders, and the system for discharging the output product. The size of a mill is usually characterized by the ratio length to diameter and this. We provide quality and efficient solutions to our global customers. We are here ...

Latest Posts

- كسارة الدولوميت المحمولة للبيع في السودان

- مسحوق الدولوميت سعر مطحنة

- الغرانيت الموردين في المملكة العربية السعودية

- تخطط المحجر محطم

- آلة تكسير الكوارتز لمصنع المعالجة

- التعدين المحمولة الكرة مطحنة

- كسارة محجر الحجر المتنقلة للبيع

- تكلفة مصنع غسل الرمال في المملكة العربية السعودية

- المطارق محطم العرض اسطنبول

- الاستفادة من ريموند مطحنة

- آلة تكسير sbm

- تستخدم أسعار آلة مسحوق الكوارتز الأبيض العراق

- تتبع كسارة الفك بريمير تراك إسبانيا

- تأجير كسارة الحجر جامبي

- حجر كسارات

- abandoned stone quarry for sale ny

- historic mining ore carts for sale

- grinder for kota stone

- relevance of rotary sand screening machine

- used equipment price india sand washing plant

- concasseur briques et des restes pause

- mesin concassage tambang

- aggregate sand washing machine sand washing plant for sale

- milwaukee model k vertical mill

- mobile crushing station nigeria giapav price

- where is granite classifierwhere is headquarters

- slag crusher plant slag crusher plant for sale

- granulator crusher exapro

- particules de charbon de fraisage

- of cone crusher russia model for iron ore