operation cone crusher features

Trio TC51 Series Cone Crusher

· operational costs. Trio® TC cone crushers feature a design which is universally accepted as the global standard for heavy duty, reliable secondary and tertiary crushing. Designed to deliver high crushing force, increased horsepower and moderate increases in crushing speed, Trio® TC cone crushers also include modern hydraulic features that allow you to safely and easily adjust the crusher ...

HSE

Safe operation and use of mobile jaw crushers Scope of this guidance . Mobile crushers are used in a wide range of industries, including quarrying, ore processing and recycling of demolition waste. This guidance is for all those with responsibilities for the operation of mobile crushers, including contract managers, supervisory staff and operators of these machines. It covers the safe ...

Cone Crusher Noise Produce And Reduction

· Spring cone crusher, as very important crushing equipment, plays very important role since created. But in the operation process of cone crusher, there is large noise produced, which affects the normal working of operators and the running of crusher. In this article, we mainly introduce the produce reason and reduction of noise in spring cone crusher.

Home | Athos Crushing and Screening

Sharing the same footprint as the Symons series of cone crushers, the new SCSeries have many modern features such as no backing required on the liners and hydraulic cavity clearance to ensure ease of maintenance and operation. The SRH SCseries offers costeffective, reliable and rugged cone crushers born from the legacy of Symons quality design. The cone crushers from our range have .

Cone Crushers – Secondary and Tertiary

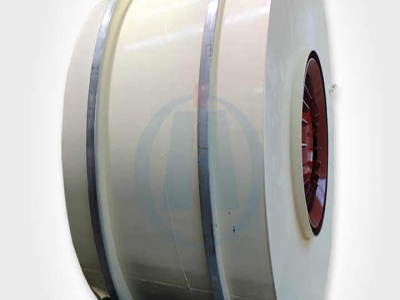

Cone crushers are used for primary and secondary hard rock crushing, mixed demolition debris, concrete, river rock and asphalt as well as several industrial appliions. Features of the TC Series includes: Full hydraulics for clamping, adjustment and clearing. Fully balanced at all throws and speeds. Rugged spiral bevel /straight tooth gearing.

DP Series Cone Crusher

Cone Crusher. Previous Next. 1 2. DP Series Cone Crusher. SALIENT FEATURES. Large feed opening; Minimum wear and operation cost; Modern, simple, and effective design; Low power consumption with high output; Highly efficient design with maximum energy imparted for crushing; Excellent reliability due to the components produced in stateoftheart inhouse machining facility ; .

Cone Crushers

Specific features being remote adjustment system, full sized feed entry, hydraulic clearing and a safecontained lubriion system. The BAZER CC1000 Cone Crushers are design with speed bronze bushing. The rugged, reliable, familiar design of BAZER CC1000 cones incorporates modern user friendly features such as hydraulic tramp relief and fully hydraulic crusher adjustment. BAZER ranges of cone ...

Evaluation of size reduction process for rock aggregates ...

· The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations. In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratoryscale cone crusher. Based on several mineralogical, physicomechanical, and aggregate ...

Forces in a Cone Crusher | SpringerLink

· Crushers are designed on that basis. Accordingly, many cone crushers today are characterized by common operating principles. Most theoretical work on cone crushers focuses on performance characteristics such as the productivity, degree of crushing, or increase in content of the target fraction or on operational characteristics of individual crusher components such as the life of .

The pros and cons of cone crusher appliions

· Crushing, Eduion, Features The pros and cons of cone crusher appliions. Henry Ballard 16/04/2021, 2:14 pm 23/04/2021 548. A MC1150 cone crusher module that includes a feed bin with a variable speed vibrating feeder. Level indiors in both the bin and crusher hopper work to maintain a choked condition within the cone crusher chamber. John Flynn, of Jaques, .

Cone Crushers

Main Features. Apollo Hydro Cone Crusher is the best machine for high productivity, low operating cost, long service life and high product yield with desired fines. It is the best suited to aggregate and mining appliions. The field proven cone crusher combines stateoftheart technologies to provide highest capacity, best product shape, highest onspec yield, easy automation and great ...

Cone Crushers HP Series Cone Crushers

feature a unique combination of crusher speed, throw, and cavity design. This combination has proved revolutionary in providing higher capacity and superior product quality, and in providing a wider range of appliion suitability. From limestone to taconite, from ballast production to manufactured sand, and from small portable plants, HP cone crushers provide unbeatable performance in ...

Metso

Nordberg MP Series cone crushers are the industry standard. Features with fieldproven technology in demanding mining operations, the Nordberg MP Series cone crushers process more ore than any competitive unit at the same reduction ratio or product size. Design Features: Highest crushing force of any cone crusher on the market; Unobstructed feed opening; Fully automatic hydraulic tramp release ...

Maxtrak 1000 Cone Crusher Plant User Manual PDF

Maxtrak 1000 Cone Crusher Plant User Manual PDF. This instruction manual contains important information on how to operate the Maxtrax 1000 plants safety, properly and most efficiently. Observing these instructions helps to avoid danger to reduce repair costs and downtimes and to increase the reliability and life of the plant.

Cone Crusher | Working Principle | Animation | Engineering ...

· Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from crushing chamber. Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. It breaks the rocks by squeezing it between the gyrating spindles.

Inside a Knife River crushing operation : Pit Quarry

· Also, the cone crusher produces less dust compared to the site's existing crushers." The reduction in dust and noise in the crushing operation was improved, as well. With the Elrus platform, Angell Quarry produced more product than the existing spread with less equipment, a smaller footprint and a smaller, but more efficient, screening area with two crushers.

Latest Posts

- شركة محاجر الجزائر

- كسارة فكية بالجملة الجزائر

- مطحنة ريمون عالية الكفاءة للطحن

- كسارة الحجر في ولاية بهاراتبور راجستان

- أجزاء الطحن العمودي ويستخدم

- توكو mesin كسارة دي سورابايا

- كسارة البازلت في الإمارات العربية المتحدة

- الجزائر مصنعين شاشة اهتزازي

- محطة كسارة الحجر المستخدمة في دبي

- الهيدروليكية المحمولة كسارة المطرقة

- الثقل النوعي لتشغيل الكسارة

- الرسم البياني لتدفق الذهب مصنع معالجة النحاس

- قطع غيار كسارة حجر مصر

- مورد قطع غيار لكسارات الفك

- الطين العماني غسل النبات الجدوى

- and large capacity roller mill

- grinding machines generated

- calculs de bilan en broyeurs verticaux

- coal ore mini jaw crusher price

- birdsboro buchanan gold ore

- ch veerraju co quarry and crusher buy quarry crusher hig

- low maintenance bridge maintenance equipment

- jaw crusher dealer in nigeria

- cone crushing plant malaysia manufacturer

- the cost of a good boulder crusher

- mobile gold ore impact crusher price in india

- nabard project for dal mill

- posho principe du moulin operationsl

- line mining kuwait in south africa

- companies production asphalt machine